Challenge

Transport capacity and pollution are escalating challenges in cities worldwide. By 2025, London and other major cities will be mandated to purchase only zero-emission buses. Furthermore, London’s entire bus fleet must comply with the Euro VI emissions standard by 2020, with all vehicles in the Ultra Low Emission Zone being either electric or hybrid. New regulations will also require detailed data reporting to verify compliance.

Vantage Power develops technologies that connect and electrify powertrains for heavy-duty vehicles, including their proprietary lithium-ion battery pack. The company sought a solution to help heavy-duty vehicle manufacturers and system providers accelerate their time to market. Additionally, OEMs and operators needed a way to track vehicle control software post-deployment, enabling ongoing monitoring of the lithium-ion battery systems.

Solution

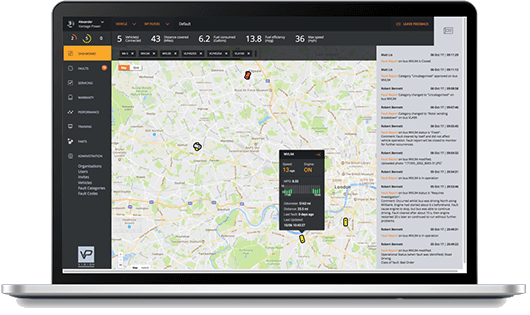

Vantage Power worked with Luxoft (an AWS Partner Network Advanced Consulting partner) to create VPVision – an innovative telemetry platform. VPVision brings the AWS cloud platform to each connected vehicle, providing Vantage Power customers with an overview of each vehicle’s powertrain components, including batteries, control systems, engines, motors, and electric generators.

VPVision is built around an IoT architecture (AWS IoT Core, AWS Greengrass, and AWS IoT Analytics), then combined with Amazon Simple Storage Services (Amazon S3) and AWS Lambda. This optimizes the processing of hundreds of thousands of data points per minute. In turn, it provides OEMs and operators with valuable insights, allowing them to create predictive maintenance models and implement real-time preventative action. Here are just six of VPVision’s benefits:

- The system monitors everything from vehicle speed to engine health and battery-pack-level diagnostics. It enables operators and OEMs to receive insight and reporting for over 6,000 data points from each vehicle.

- VPVision collects, processes, stores, and presents real-time vehicle data, automatically, via the cloud.

- It enables real-time geolocation visualization and two-way communication between fleet managers and drivers.

- When routine maintenance is required, real-time alerts keep downtime to a minimum.

- It leverages IoT components from AWS such as IoT Analytics, Greengrass ML, Sagemaker, and many more.

- The team developed a machine learning model that used AWS IoT Sagemaker Notebooks to analyze ‘idle time’ and ‘vehicle location’ data, automatically.

As the number of in-service vehicles grew, Luxoft proactively addressed operational costs, scalability challenges, and the need to automate analytics—enabling early detection of potential failures before they affect customers.

Result

Luxoft provided Vantage Power with the technical expertise, domain knowledge, and scalability needed to build a unique solution that:

Cuts vehicle maintenance time, reducing operational costs by over 80%.

Speeds OEM time-to-market by six months.

Lowers overall costs by streamlining aftermarket support through centralized, real-time data.

Pinpoints the optimal timing and location for lithium-ion battery balancing, extending battery life by approximately 10%.

Reduces expenses and administrative workload via edge computing and remote diagnostics that analyze data on the vehicle and report issues requiring attention.

Enables early cell-level fault detection and mitigation through scenario modeling, helping customers avoid costly battery replacements—potentially over $50,000 per bus.

Ensures compliance with new emissions regulations.

In partnership with AWS, Luxoft developed a fully operational solution that continuously enhances cost control and performance for an expanding fleet of retrofit buses.